Products

Material charging height is low, and product discharging height is high.

1. Even mixing and stirring without scorching.

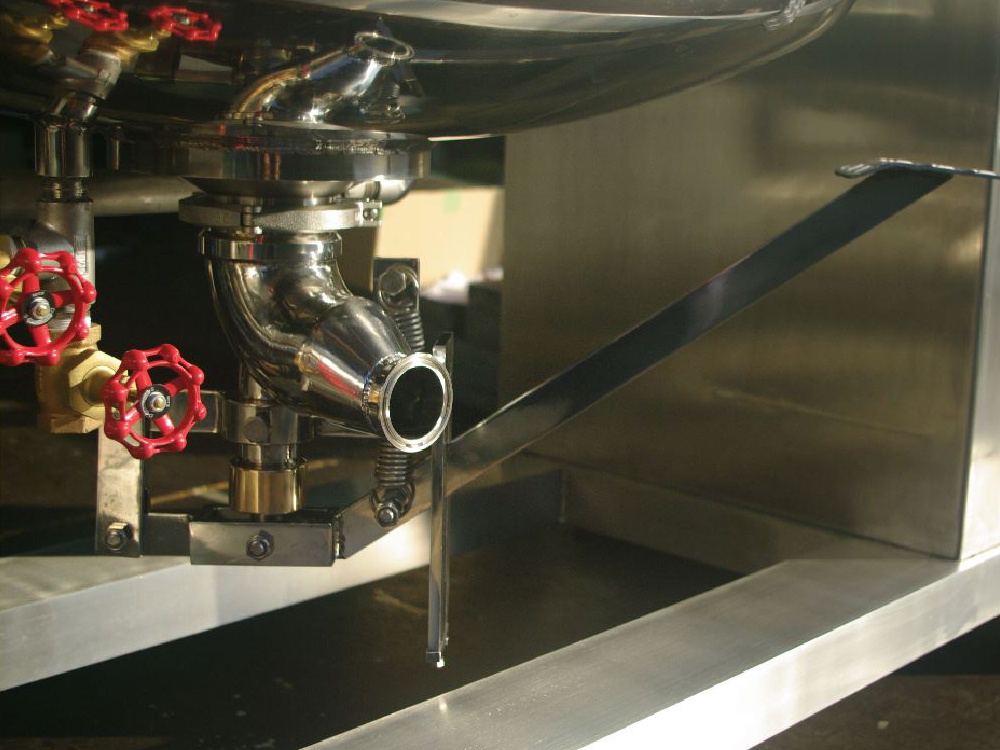

The mixing blades perfectly fitting to the shape of the vessel to scrape the food product perfectly thus enables mixing with no scorching. The mixing blades can be easily detached which makes it hygienic. The bigger heat-transfer area means faster heating and excellent cost performance.

2. Steam heating is easy for maintenance.

In steam heating, centralized management and maintenance of steam is easy and therefore very safe. Maximum steam pressure is 0.3MPa which is suitable for high-temperature cooking.

Applications

Red bean paste, Jam, Custard cream, Meat sauce, Ramen noodle soup, Korean style BBQ sauce, Frozen foods, Meat bun filling, Ketchup, Curry, Hamburger, Croquette filling, etc.

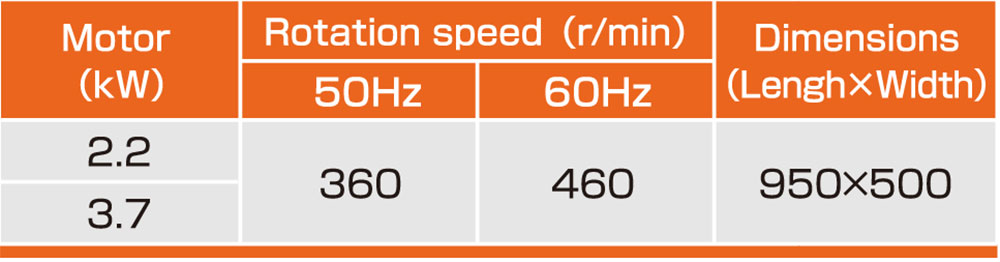

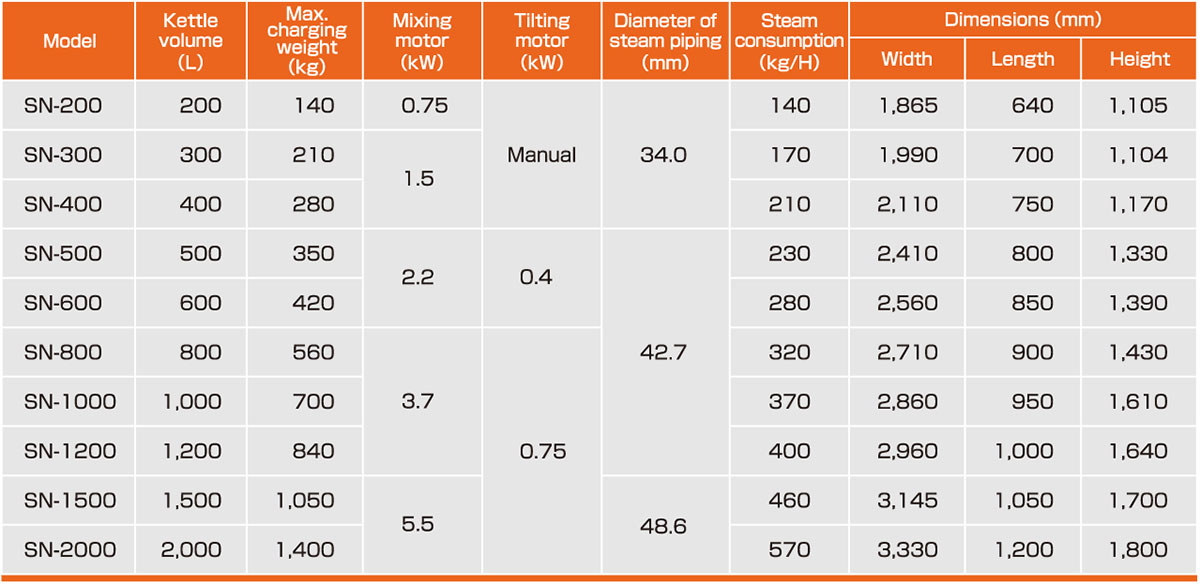

■ Specifications of SUN KNEADER Model SN.

※We manufacture machines with kettle volume in the range of 100L~3,000L.

※Mixing speed is 6~24r/min.

※Options: Electric cover, eccentric tilting, self-weighing system, product discharge valve, automatic operation, cooling system.

※Max charging weight might change according to the product item.

Standard features

Options

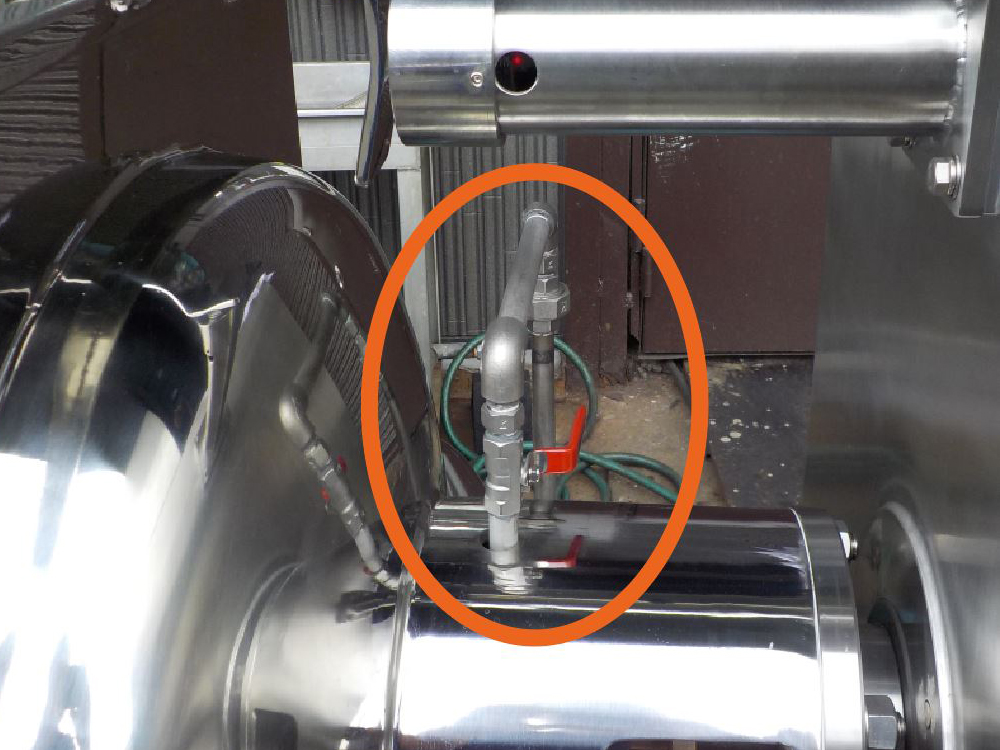

by steam flushing

(Foot operated tank valve)

(Auto cylinder valve)

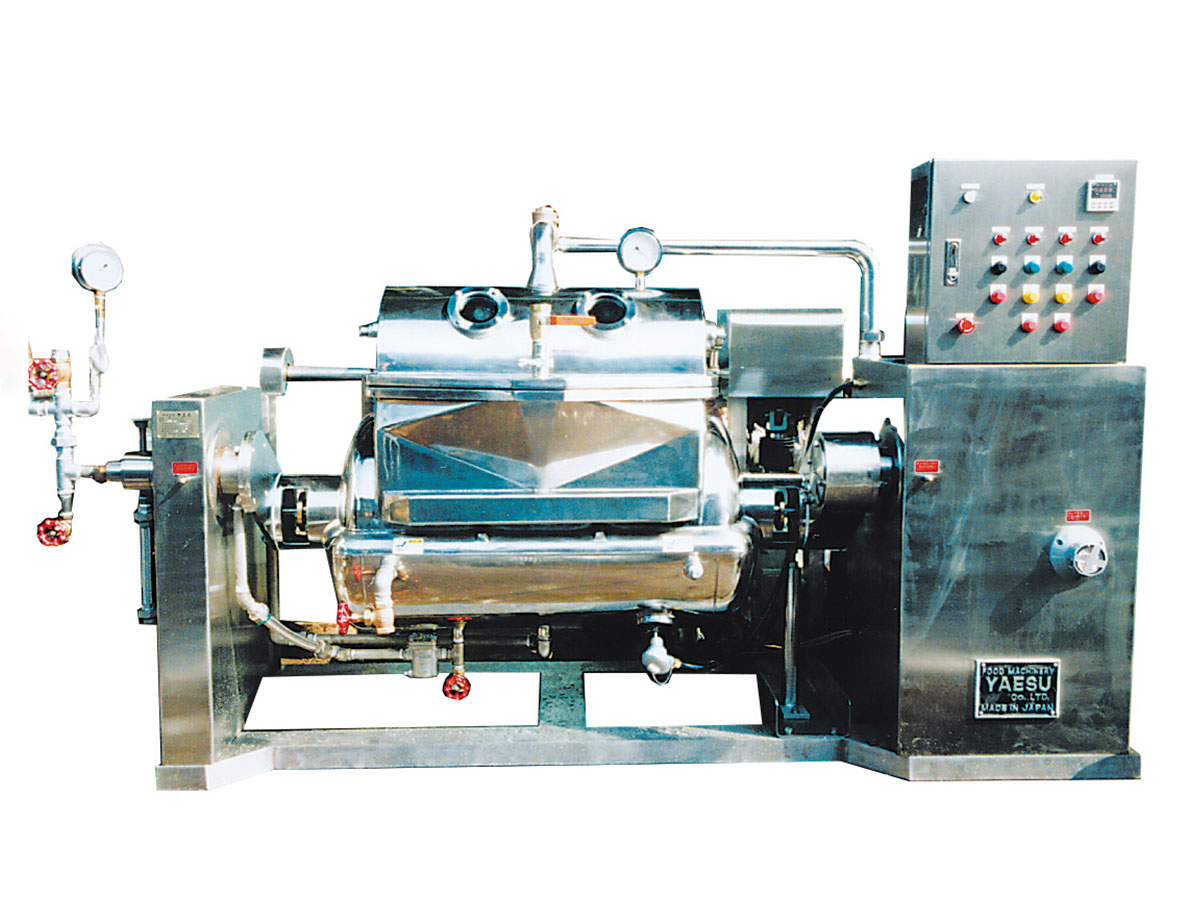

1. Time of heating concentration and cooling can be drastically shortened.

By reducing the pressure in the kettle, the food product is cooled down by the heat of evaporation, which prevents food deterioration.

2. Prevents bacterial contamination and oxidation of the food.

The food product is cooked in the closed vacuum condition, and contamination of the falling bacteria is prevented.

Applications

Red bean paste, Jam, Fruit paste, Custard cream and Vacuum cooling, Low temperature concentrated cooking, Mixing, Degassing, etc.

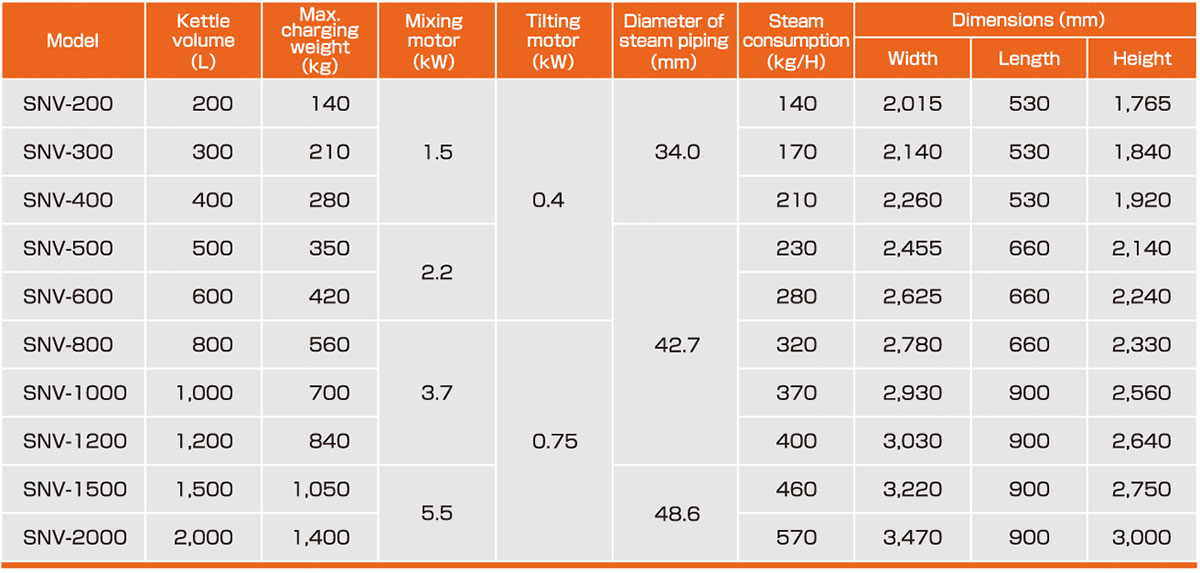

■ Specifications of Vacuum Type SUN KNEADER Model SNV.

※We manufacture machines with kettle volume in the range of 100L~3,000L.

※Mixing speed is 6~24r/min.

※Options: eccentric tilting, self-weighing system, product discharge valve, automatic cooking, cooling system.

※Max charging weight might change according to the product item.

Needle blades rotate at 60~80r/min. The blade structure is effective for lump crushing and mixing.

Applications

Miso ramen noodle soup, Korean style BBQ sauce, Curry, etc.

●Kettle volume: 300L~3,000L.

Cooking temperature goes very high with gas heating which steam heating cannot achieve. Wide range of foods can be cooked effectively such as high viscosity product to product with lots of solid ingredients.

Applications

Curry roux, Stir fry, Chinese cuisine, etc.

●Kettle volume: 100L~2,000L.

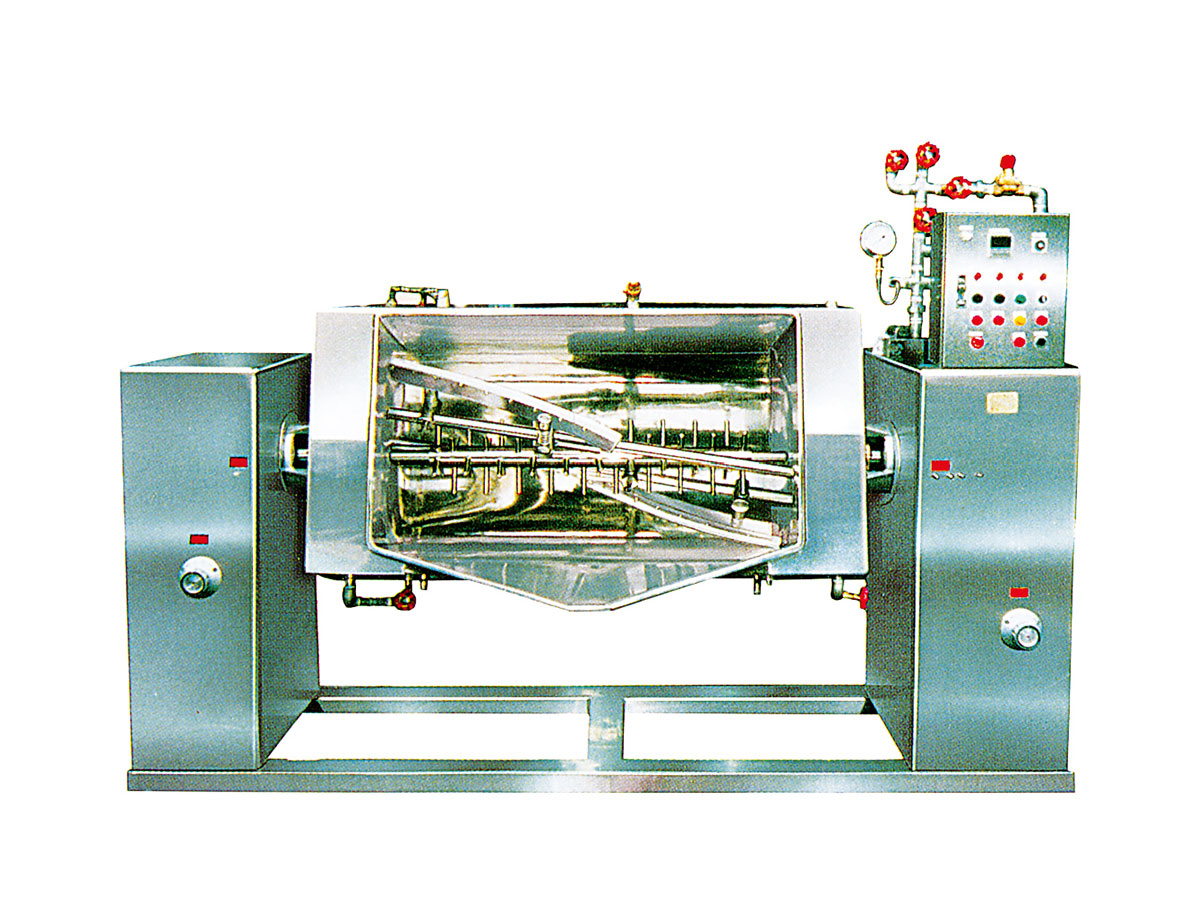

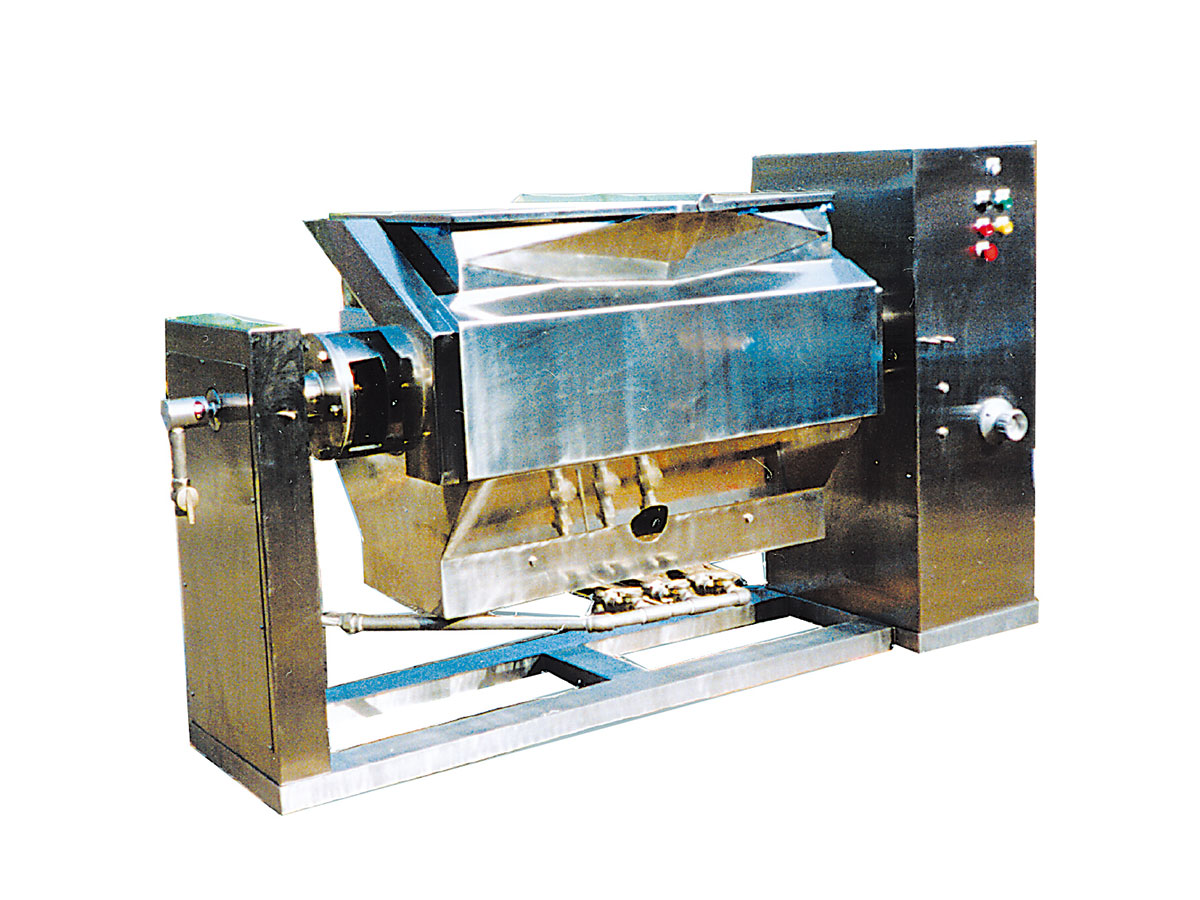

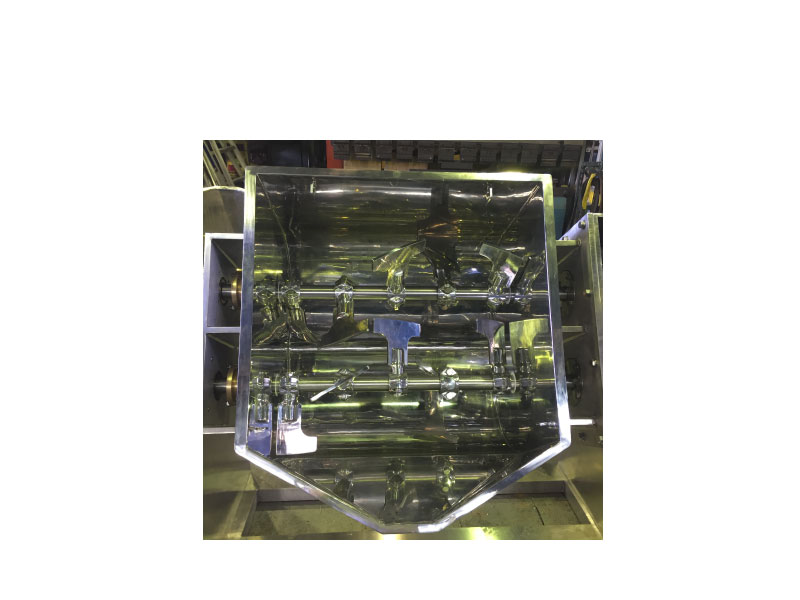

Different rotation speed type: 2 mixing shafts with the different rotation speed increases friction between the food products which then enforces powerful kneading. Same rotation speed type: 2 mixing shafts with the same rotation speed can knead high viscosity food product with the effect of overlapping the locus of the mixing blades.

Applications

Dumpling filling, Butter, Baking powder, Chewing gum, Chocolate, Cheese, Powder milk, Spices, etc.

●Kettle volume: 100L~2,000L.

The natural flow of the food product in the hemispherical kettle and hand-turning effect from the original mixing blades brings effective mixing solutions. In particular this combination allows gentle mixing of high viscosity product and delicate food product.

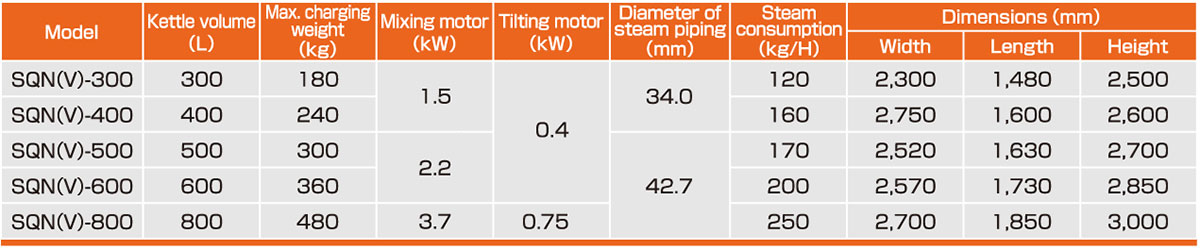

■ Specifications of SUN KNEADER Model SQN & SQNV.

※We manufacture machines with kettle volume in the range of 60L~3,000L.

※Options: Pouring spout, self-weighing system, product discharge valve, cooling system, timer, semi-automated cooking, automated cooking.

※We manufacture vacuum type and pressure and vacuum type as well.

※Max charging weight might change according to the product item.

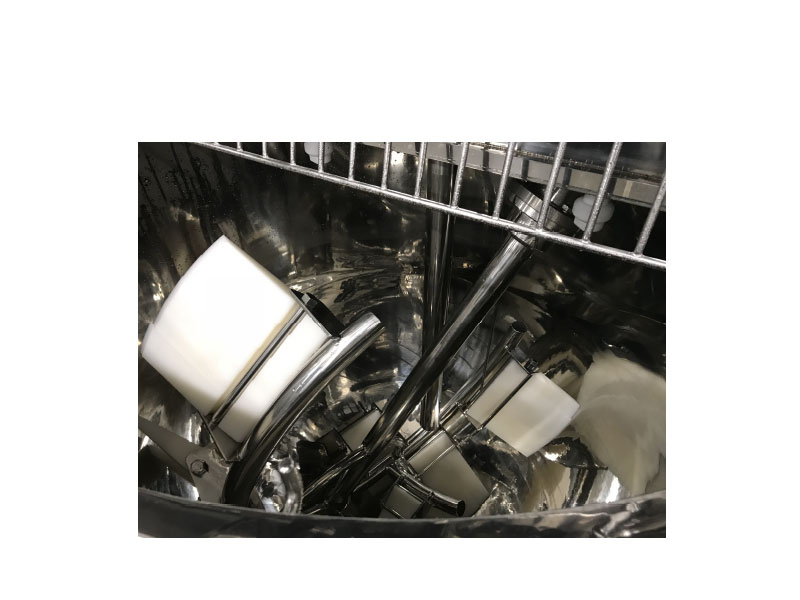

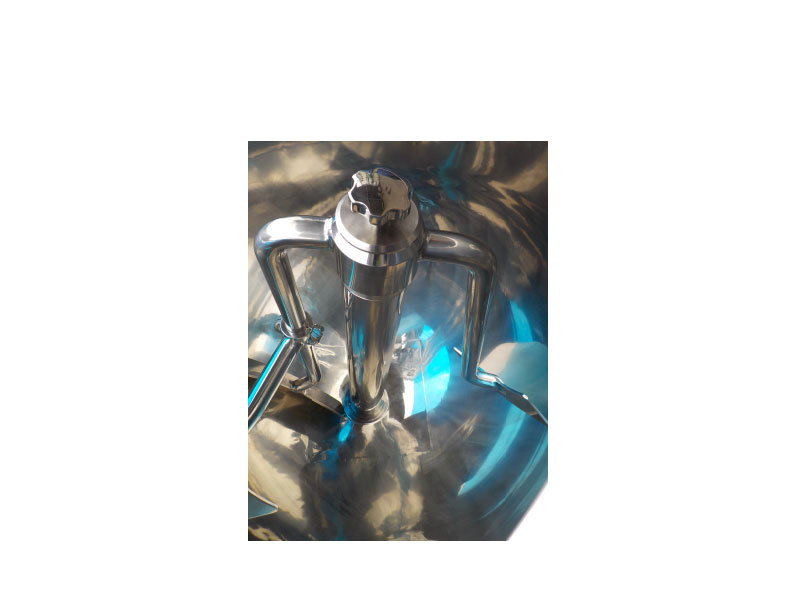

Combination of oblique shaft mixing and hemispherical kettle enhances effective mixing in both horizontal and vertical directions which helps to stabilize quality of the food product.

Applications

Seasoning foods, Cooking sauce, Soup, Sauce, Mayonnaise, Dressing, Miso, Jam, Flour paste and other Pasty foods, Cosmetics, Oil, Fat, etc.

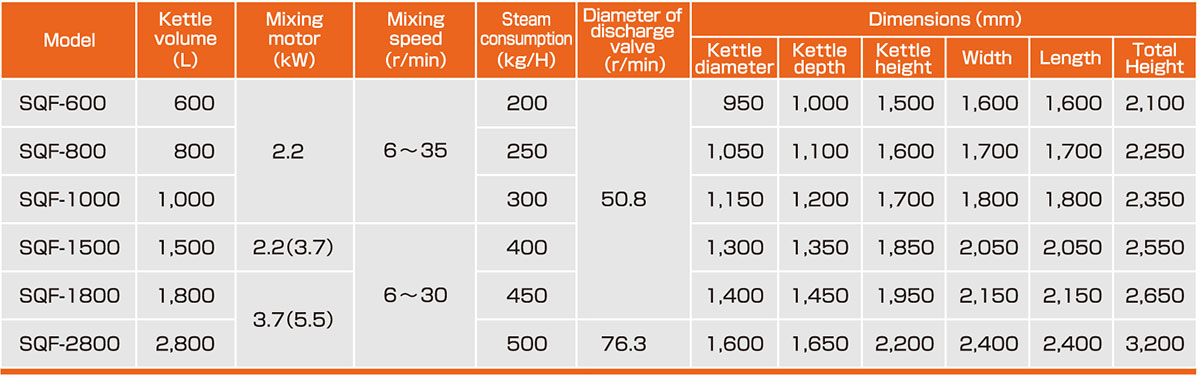

■ Specifications of Oblique Shaft Mixer Model SQF.

※We design and manufacture various kinds of machines according to your requests.

Steam is easily controlled and managed therefore safe choice of heat source. Maximum steam pressure is 0.3MPa which is suitable for high temperature cooking.

Applications

Soup, Spaghetti, Macaroni, Sauce, Congee, Pudding, Jelly, Concentrated heating, Stewing, Seasoning, etc.

■ Specifications of Steam Kettle.

※Soup, Spaghetti, Macaroni, Sauce, Congee, Pudding, Jelly, Concentrated heating, Stewing, Seasoning, etc.

※Max charging weight might change according to the product item.

The mixing blades rotate horizontally or obliquely, which enables the food product to be mixed evenly without any damage. The bearing is attached over the liquid surface making it very hygienic.

Applications

Soup, Sauce, Spaghetti, Macaroni, Sauce, Congee, Pudding, Jelly, Concentrated heating, Stewing, Seasoning, etc.

■Specifications of Floor Mixer Model SQF.

※Options: Pouring spout, product discharge valve, top cover, self-weighing system.

The oblique stirrer brings effective mixing in both vertical and horizontal direction. In addition, the automatic rotation and revolution of the mixing shaft makes no dead point in mixing, making sure food product is not scorched, not damaged and mixed evenly.

Application

Filling, Sauté, Stir-fry, Roux, Sauce, Soup, BBQ Sauce, Red bean paste, Caramel, Custard cream, Fondant, etc.

■Specifications of Steam Heating Mixer Model SK-M.

※Options: Pouring spout, product discharge valve, top cover, temperature sensor, self-weighing system.

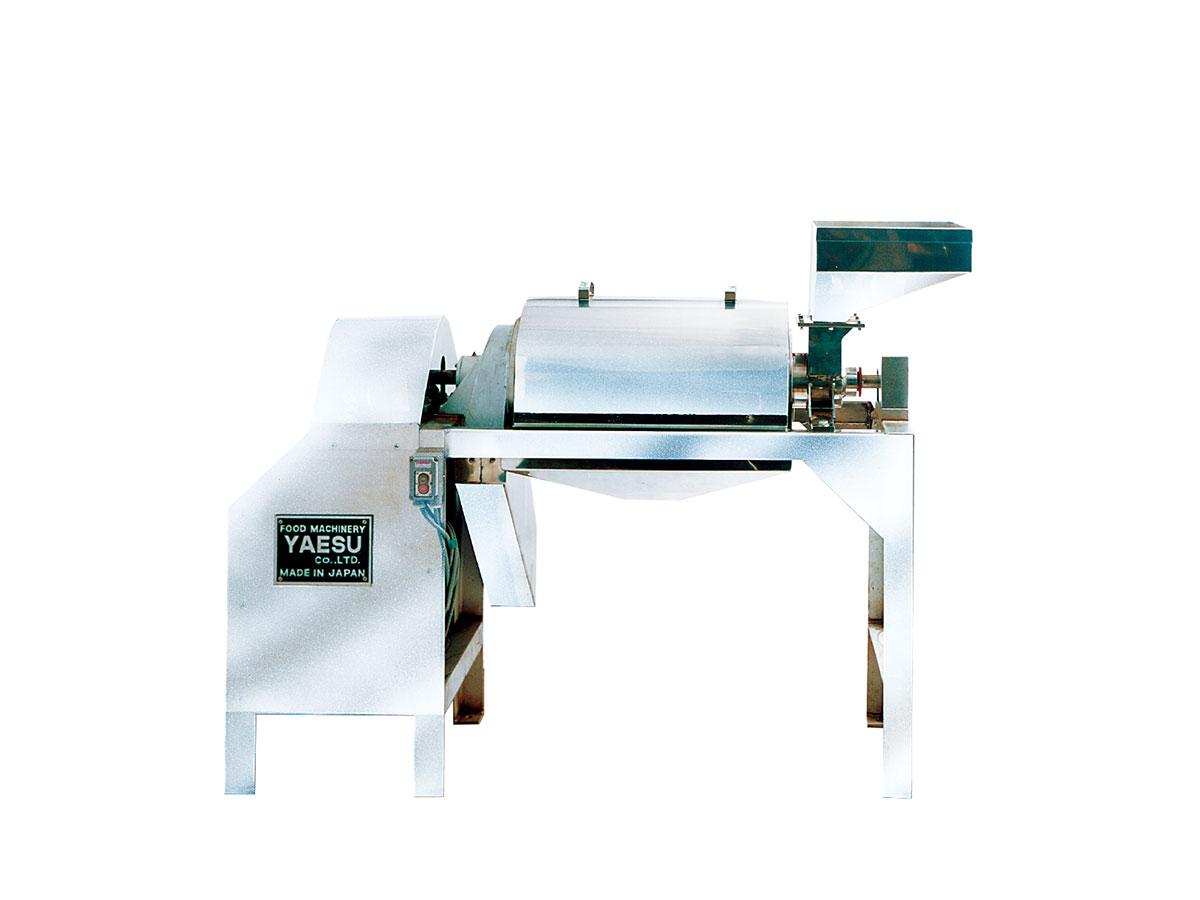

1. Shape of the pan can be selected according to the food item.

Shallow pan with bigger diameter is suitable for stir-fry and roux production. Pan with moderate depth like a double jacketed kettle is suitable for stewing.

2. Food product is evenly mixed and stirred.

Rotating and revolving scrapers evenly mix and stir the food product without scorching. Mixing speed is adjustable according to the food item.

Applications

Curry roux, White roux, Meat bun filling, Hamburg, Dumpling filling, Spring roll filling, Fried vegetable, Sautéed onion, etc.

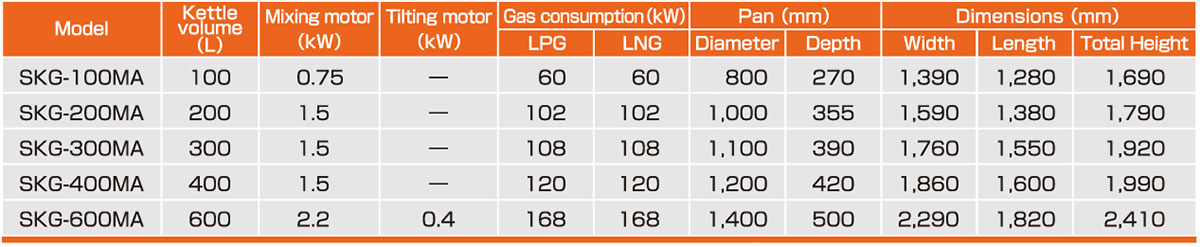

■ Specifications of Gas Heating Mixer Model SKG-M.

※Options: Temperature sensor, temperature control, electric pan tilting, electric stirrer tilting.

Fruit pulp, juice, skin, seeds, and other impurities of the ingredient are effectively separated and strained in large quantities. The food product is taken to the upper pulper screen then to the lower finisher, which assures the product to be extremely high quality with fine particles. All food contact surfaces are made of stainless steel which is acid resistant and hygienic. The bearing and the other parts can be washed with water.

Applications

Tomato puree, Tomato ketchup, Apple jam, Sauce, White sauce, Red bean paste, Curry roux.

■Specifications of Pulper Finisher Model HC.

※Machine ability might differ according to the product item.

The spiral-shaped feeding device and the cutter attached to the tip enable the ingredient to be chopped to the most suitable size. All food contact surfaces are made of stainless steel which is acid resistant and hygienic. The bearing and the other parts can be washed with water.

Applications

Fruits, Vegetables, Ground meat, Fish, etc.

■Specifications of Fruit Chopper Model 52.